Intro to Polypropylene Fibers for Concrete

Polypropylene fibers are revolutionizing the building and construction sector by improving the performance and resilience of concrete. These artificial fibers, made from polypropylene, offer remarkable advantages that address crucial obstacles in modern-day construction. This short article delves into the residential or commercial properties, applications, market fads, and future prospects of polypropylene fibers in concrete, revealing their transformative effect on structure techniques.

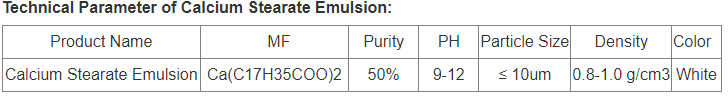

(TRUNNANO Polypropylene (PP) Fibers)

The Toughness and Convenience of Polypropylene Fibers

Polypropylene fibers have distinct physical and chemical residential properties that make them excellent for reinforcing concrete. Lightweight yet solid, these fibers significantly enhance tensile toughness, crack resistance, and influence resistance. Their non-corrosive nature makes certain long-term resilience, reducing maintenance prices and prolonging the life-span of structures. Moreover, polypropylene fibers improve workability and pumpability, making them crucial in large construction tasks. The capability to endure extreme ecological conditions additionally solidifies their duty as a dependable construction product.

Applications Throughout Diverse Building And Construction Projects

1. Concrete Reinforcement: Polypropylene fibers play a crucial function in strengthening concrete, particularly in high-performance concrete (HPC) and self-consolidating concrete (SCC). They stop micro-cracking throughout the early stages of hydration, improving the total honesty of the structure. In precast aspects and shotcrete applications, polypropylene fibers make sure consistent circulation and consistent performance. Their addition decreases the need for traditional reinforcement methods, using affordable services without endangering high quality.

2. Fire Resistance and Security: One of the standout functions of polypropylene fibers is their payment to fire safety and security. When revealed to high temperatures, polypropylene melts and develops gaps within the concrete matrix. These gaps work as pressure relief channels, preventing eruptive spalling– a sensation where concrete pieces displace because of inner stress buildup. Enhanced fire resistance not just secures the architectural integrity however also safeguards human lives. The combination of polypropylene fibers in fire-prone locations like tunnels and commercial facilities highlights their value in safety-critical applications.

3. Sustainability and Environmental Influence: As sustainability ends up being a concern in building, polypropylene fibers supply green options. Derived from recycled materials, they reduce waste and reduced carbon impacts. The use of polypropylene fibers can reduce the amount of cement required, leading to reduced carbon dioxide exhausts. In addition, their longevity lessens the demand for repair services and substitutes, promoting resource efficiency. Accepting lasting experiment polypropylene fibers aligns with worldwide initiatives to develop greener and extra resilient infrastructure.

Market Trends and Development Drivers: A Positive Point of view

1. Developments in Building And Construction Innovation: Fast improvements in building and construction modern technology demand ingenious products that improve performance and efficiency. Polypropylene fibers meet this requirement by supplying superior reinforcement and adaptability. Smart products and progressed monitoring systems better increase their application scope, setting brand-new criteria in the sector. The integration of polypropylene fibers in advanced construction practices showcases their flexibility and future-proof nature.

2. Increasing Concentrate On Safety and Sturdiness: With expanding concerns over safety and security and longevity, polypropylene fibers have ended up being important in building resilient and resilient structures. Their ability to avoid micro-cracking and offer fire resistance addresses essential issues in structure style. The emphasis on safety criteria and long-lasting efficiency settings polypropylene fibers as a preferred selection for engineers and designers. The fostering of these fibers in high-risk atmospheres highlights their role in ensuring architectural stability and passenger safety and security.

3. Economic Conveniences and Cost Efficiency: Incorporating polypropylene fibers supplies significant financial advantages. Minimized labor costs, fewer reinforcements, and decreased upkeep requirements convert to substantial savings over the lifecycle of a job. For programmers and specialists, the cost-effectiveness of polypropylene fibers makes them an appealing alternative without endangering high quality. The equilibrium in between efficiency and price makes sure widespread adoption across various building industries.

Difficulties and Limitations: Navigating the Path Forward

1. Technical Experience and Implementation: Successfully incorporating polypropylene fibers right into concrete calls for specialized understanding and competence. Professionals and engineers should comprehend optimal does, blending strategies, and positioning techniques to maximize benefits. Connecting the void between academic advantages and useful application will be critical for more comprehensive fostering. Supplying detailed training and guidelines can encourage stakeholders to harness the full potential of polypropylene fibers.

2. Standardization and Policy: Making sure constant top quality and performance requires standard screening and regulative frameworks. Variations in fiber production and application can lead to irregular results, influencing structural stability. Establishing durable criteria and certifications will cultivate trust and dependability in using polypropylene fibers. Partnership in between suppliers, scientists, and regulative bodies will certainly be vital in developing globally accepted standards.

( TRUNNANO Polypropylene (PP) Fibers)

Future Prospects: Advancements and Opportunities

The future of polypropylene fibers in concrete appearances promising, driven by the boosting need for lasting and high-performance products. Ongoing research and development will bring about the creation of brand-new fiber types and applications, even more increasing their energy. Advancements in clever products, 3D printing, and green chemistry will certainly boost the value proposition of polypropylene fibers. As sectors prioritize efficiency, sturdiness, and environmental duty, polypropylene fibers are poised to play a critical role fit the future of building. The constant development of these fibers guarantees exciting possibilities for advancement and growth.

Verdict: Accepting the Potential of Polypropylene Fibers for Concrete

Finally, polypropylene fibers are changing the building and construction sector by improving the performance, sturdiness, and sustainability of concrete. Their special buildings and considerable applications supply significant benefits, driving market development and advancement. Comprehending the advantages and obstacles of polypropylene fibers allows stakeholders to make informed decisions and capitalize on arising possibilities. Accepting polypropylene fibers implies welcoming a future where technology satisfies durability in building and construction.

High-grade Polypropylene Fibers Provider

Cabr-Concrete is a supplier of Concrete Admixture under TRUNNANO with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high quality what is polypropylene fibre, please feel free to contact us and send an inquiry(sales5@nanotrun.com).

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us