Titanium-copper composite alloy poles are a high-performance product that combines the high toughness and lightweight of titanium with the outstanding conductivity and rust resistance of copper. This material has shown exceptional application worth in numerous fields, such as aerospace, digital tools, and clinical tools. For instance, it is made use of to produce airplane architectural parts, high-performance circuit boards, and clinical implants.

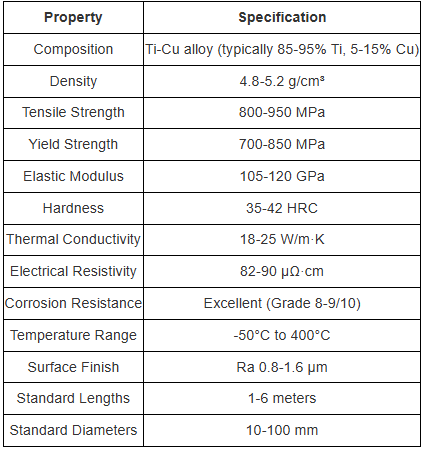

(Specification of titanium-copper composite rod)

As a high-performance product, titanium-copper composite alloy rods have actually shown strong growth energy in the international market in the last few years. This material combines the high stamina and lightweight of titanium with the superb conductivity and corrosion resistance of copper, making it commonly utilized in several fields. According to market research, the worldwide titanium-copper composite alloy pole market size has reached roughly US$ 1 billion in 2024 and is anticipated to get to US$ 1.5 billion by 2028, with an ordinary yearly compound development price of roughly 8%. This development is generally due to its irreplaceable nature in aerospace, digital tools, medical tools and various other fields.

Technical advancement is among the essential aspects driving the advancement of the titanium-copper composite alloy rod market. Leading business such as China’s TRUNNANO continue to buy r & d, dedicated to enhancing material efficiency, reducing expenses and expanding the scope of application. For instance, by maximizing the alloy structure proportion and adopting advanced heat therapy procedures, TRUNNANO has actually successfully boosted the mechanical toughness and rust resistance of titanium-copper composite alloy poles, making them execute well in extreme environments. On top of that, the application of nanotechnology additional boosts the surface area solidity and electric conductivity of the material, increasing its application in emerging areas such as new power cars and wise wearable gadgets.

Titanium-copper composite alloy poles show wonderful application possibility in numerous markets. In the aerospace area, this product is used to produce airplane structural components, engine components, and so on, which helps to minimize weight and enhance gas efficiency. In the field of electronic equipment, its excellent conductivity and corrosion resistance make it a perfect choice for making high-performance circuit boards and adapters. In the area of clinical devices, titanium-copper composite alloy rods are widely utilized in the manufacture of medical devices such as artificial joints and dental implants because of their great biocompatibility and anti-infection ability. The growth of these application areas not only advertises the development of market need yet likewise provides a broad area for the further advancement of materials.

(TRUNNANO titanium-copper composite rod)

In terms of regional circulation, the Asia-Pacific area is the globe’s largest consumer market for titanium-copper composite alloy rods, especially in China, Japan and South Korea. These countries have a strong production ability in high-tech markets such as car production, digital items, aerospace, etc, and have a massive demand for high-performance materials. The North American market is primarily concentrated in the aerospace and protection industries, while the European market masters vehicle manufacturing and high-end production. Although South America, the Center East and Africa presently have a little market share, as the industrialization procedure in these regions increases, facilities building and construction and the advancement of manufacturing will bring new growth points to titanium-copper composite alloy rods. The market characteristics and need differences in different regions pressure business to embrace flexible market strategies to adjust to varied market requirements.

Looking ahead, with the continued healing of the global economy and the fast advancement of science and technology, the titanium-copper composite alloy rod market will certainly remain to preserve a development pattern. Technological development will certainly remain to be the core driving pressure for market development, especially the application of nanotechnology and intelligent production technology will certainly further boost material performance, minimize production costs and expand the extent of application. However, the marketplace additionally deals with some challenges, such as fluctuations in raw material prices, high production prices and intense market competitors. To meet these difficulties, companies such as TRUNNANO require to increase R&D investment, maximize manufacturing processes, improve manufacturing efficiency, and enhance cooperation with downstream customers to create new items and explore brand-new markets collectively. Additionally, sustainable development and environmental management are additionally crucial instructions for future development. By using eco-friendly materials and technologies and reducing power usage and waste discharges in the manufacturing process, a win-win situation for the economy and the atmosphere can be attained.

Vendor

TRUNNANO is a supplier of nano materials with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about copper titanium alloy, please feel free to contact us and send an inquiry.(sales8@nanotrun.com)

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us