Improvements in Spherical Niobium Powder: Driving Innovation and Sustainability Throughout High-Tech Industries

Round niobium powder stands as a testament to the continuous improvements in material scientific research, playing a significantly important role in contemporary industries. Niobium, recognized for its high melting point, low density, and excellent rust resistance, discovers itself changed into a versatile round powder type that supplies unrivaled advantages. This sort of powder is produced utilizing sophisticated methods like gas atomization or plasma spheroidization, making sure bits are flawlessly rounded with consistent dimension distribution. Such attributes considerably boost flowability and packing thickness, which are essential variables for applications in additive manufacturing and steel shot molding. The one-of-a-kind residential or commercial properties of round niobium powder allow it to hold up against extreme environments, making it vital in aerospace parts, superconducting magnets, and other high-performance products. Furthermore, this powder’s capacity to perform electrical power and warm effectively, along with its compatibility with human tissue, opens up brand-new opportunities in electronic devices and medical tools. As research and development efforts remain to discover novel applications, round niobium powder is readied to play an essential role in shaping the future of modern technology and sector.

(Spherical Niobium Powder)

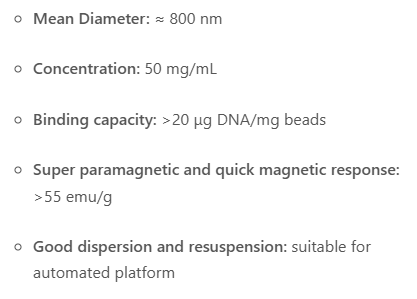

The production process of round niobium powder is a wonder of engineering accuracy and advancement. Producers take advantage of sophisticated innovations to generate powders that satisfy the rigorous needs of numerous markets. Gas atomization includes splashing molten niobium via a nozzle into a chamber where it strengthens right into round beads upon contact with a cooling tool. Additionally, plasma spheroidization uses high-energy plasma to melt angular niobium powders, which then cool swiftly into spheres. Both techniques result in powders that display very little porosity and superior mechanical buildings contrasted to their irregularly shaped equivalents. The boosted flowability and uniformity of spherical niobium powder make it specifically appropriate for 3D printing, where it can be made use of to create intricate geometries with phenomenal strength and durability. Beyond additive production, this powder works as a necessary part in the production of superalloys, adding to enhanced performance in jet engines and commercial wind turbines. In the world of electronic devices, the powder’s conductivity and thermal security sustain the development of extra reliable capacitors and resistors. Medical applications take advantage of niobium’s biocompatibility, bring about the development of implants that decrease the threat of being rejected by the body. With each passing day, the prospective applications for spherical niobium powder expand, driven by the relentless quest of advancement across several industries.

As the need for high-performance products grows, so too does the market for round niobium powder. Industries such as aerospace, automobile, and electronic devices are progressively reliant on this powder to meet the obstacles of miniaturization, effectiveness, and sustainability. Aerospace suppliers utilize niobium-based alloys for components that should sustain extreme temperatures and stress, making certain trustworthy procedure in space missions and commercial flights. Automotive firms check out using spherical niobium powder in electrical lorries, leveraging its light-weight properties to improve gas performance and expand driving range. Electronic devices producers value the powder for its function in developing small and long lasting electronic gadgets with the ability of running under diverse conditions. Additionally, the clinical field capitalizes on niobium’s biocompatibility to create cutting-edge options for client treatment. Environmental factors to consider also favor the adoption of spherical niobium powder, as niobium mining methods are typically a lot more sustainable than those of some alternative metals. Reusing efforts further promote a circular economy by recuperating and recycling niobium from end-of-life items. As understanding of these advantages spreads, investment in round niobium powder is likely to raise, cultivating technological development and increasing its energy in a world significantly focused on advanced products and lasting practices. The continued development of round niobium powder assures to unlock new chances for technology across a vast array of markets.

TRUNNANO is a supplier of nano materials with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about Spherical Niobium Powder, please feel free to contact us and send an inquiry.(sales5@nanotrun.com)

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us